The Antminer S21 XP Hyd is a powerful mining machine, and maintaining its coolant system is crucial to ensure optimal performance.

To effectively maintain the coolant system in the Antminer S21 XP Hyd, regularly inspect coolant levels, ensure the use of high-quality coolants, maintain appropriate flow rates and pressure, and routinely check system components for wear or leaks. These practices help prevent overheating and extend the device’s lifespan.

While these basic steps provide a good starting point for maintenance, understanding the nuances of each procedure can make a significant difference. Read on to explore detailed maintenance tips that will keep your Antminer running smoothly and efficiently.

What Are the Best Practices for Checking Coolant Levels?

Regularly checking your vehicle’s coolant levels is vital for engine health and preventing overheating. Learn best practices to ensure optimal performance and longevity of your car’s cooling system.

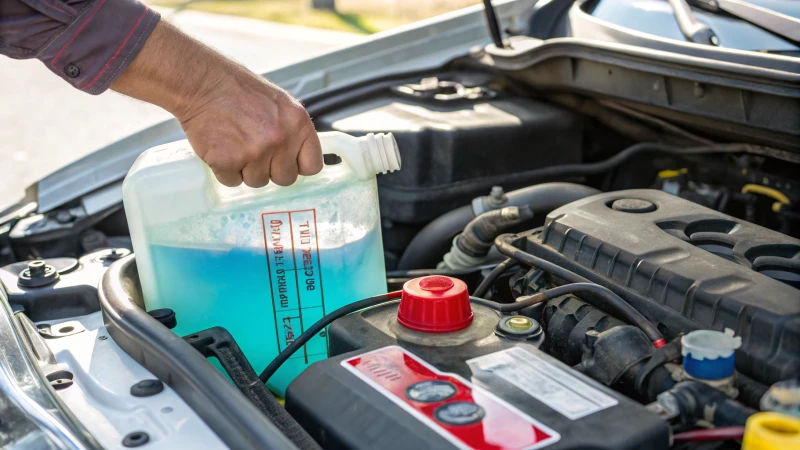

To effectively check coolant levels, ensure the engine is cool, locate the coolant reservoir, and verify levels against the indicator marks. Regularly inspect for leaks and maintain coolant quality by using recommended fluids.

Step-by-Step Guide to Checking Coolant Levels

- Ensure Engine Coolness: Always check the coolant level when the engine is cool to avoid burns from hot steam or fluid.

- Locate the Coolant Reservoir: Most vehicles have a translucent reservoir with indicator marks showing ‘min’ and ‘max’ levels. Consult your owner’s manual if unsure about its location.

- Verify Coolant Level: The coolant should be between the ‘min’ and ‘max’ marks. If low, add the recommended type of coolant. Avoid overfilling to prevent system pressure issues.

- Check for Leaks: Inspect hoses and connections for signs of leaks or wear. Leaks can lead to low coolant levels and engine overheating.

- Maintain Coolant Quality: Use the correct type of coolant for your vehicle and periodically test its pH level. This helps prevent corrosion and maintain efficiency.

Why Coolant Quality Matters

Using high-quality, manufacturer-recommended coolants ensures your cooling system functions efficiently. Poor-quality fluids can cause corrosion or buildup, leading to costly repairs.

| Coolant Type | Benefits | Potential Issues |

|---|---|---|

| Antifreeze | Prevents freezing, reduces rust | Incompatible with certain engines |

| Deionized Water | Minimal impurities | May not provide rust protection |

Understanding Coolant Indicators

Modern vehicles often feature dashboard indicators that alert drivers to cooling system issues. Familiarize yourself with these symbols in your vehicle’s manual to respond promptly to warnings.

Anticipate seasonal changes by adjusting your coolant mixture accordingly. For example, increase antifreeze concentration in colder months to prevent freezing.

By incorporating these practices into your routine maintenance, you ensure your vehicle remains reliable and efficient, avoiding unexpected breakdowns and costly repairs.

How to Choose the Right Coolant for Your Antminer?

Choosing the right coolant for your Antminer is vital for maintaining its efficiency and preventing overheating. With various options available, understanding which one suits your mining setup can significantly enhance performance.

Select a coolant based on your Antminer’s specifications and environmental conditions. Consider factors such as coolant composition, thermal conductivity, and corrosion prevention to ensure optimal performance and longevity of the mining equipment.

Understanding Coolant Types

Choosing the right coolant involves understanding the different types available. Generally, coolants for Antminers fall into three categories:

- Water-based coolants: These include deionized or distilled water. They offer excellent thermal conductivity but require anti-corrosion additives.

- Glycol-based coolants: Often used in colder climates, they prevent freezing. Look for a mix suitable for the temperature range in your area.

- Specialized mining coolants: Formulated specifically for mining rigs, they offer enhanced heat transfer properties and anti-corrosion benefits.

Considerations for Coolant Selection

When selecting a coolant, consider these factors:

| Factor | Description |

|---|---|

| Thermal Conductivity | Ensure it efficiently transfers heat away from the miner. |

| Corrosion Inhibition | Prevents damage to metal parts. |

| Freezing Point | Important if your setup is in a cold environment. |

Maintaining Coolant System Efficiency

Once you’ve chosen a coolant, maintaining your cooling system is key:

- Regular Inspections: Check for leaks or low levels frequently.

- Monitor Flow Rate: Aim for an optimal flow rate between 8-10 L/min.

- Pressure Checks: Keep system pressure around 3.5 bar to maintain efficiency.

Environmental and Operational Conditions

The environment in which your Antminer operates also influences coolant choice. High humidity or temperature variations may necessitate specific types or additives.

For instance, in humid conditions, consider using inhibitors to combat moisture-related issues. In extremely hot climates, enhanced thermal conductivity becomes more crucial to prevent overheating.

Technical Specifications and Compatibility

Always refer to your Antminer’s manual for recommended specifications on coolant type and properties. This ensures compatibility and avoids warranty voiding due to inappropriate coolant usage.

Why Is Monitoring Flow Rate and Pressure Crucial?

Ensuring accurate flow rate and pressure monitoring is vital in various systems, like cooling or HVAC, to maintain efficiency, prevent damage, and optimize performance. Understanding these parameters helps in troubleshooting and system design.

Monitoring flow rate and pressure ensures systems operate efficiently, preventing overheating or mechanical failures. Proper management aids in achieving optimal performance, energy conservation, and system longevity, crucial for reliable operations.

Importance in Cooling Systems

In systems such as the Antminer S21 XP Hyd, monitoring flow rate and pressure is key. The coolant flow rate should be maintained between 8.0 to 10.0 L/min, while the pressure should hover around 3.5 bar. This balance is crucial to ensure that the system remains within safe operational limits, preventing overheating and ensuring optimal mining performance.

HVAC Systems: A Balancing Act

In HVAC systems, precise control of flow rate and pressure is essential for energy efficiency and comfort. The system’s capacity to maintain a stable environment relies on monitoring these parameters. Mismanagement can lead to increased energy consumption and reduced lifespan of equipment.

| Parameter | Ideal Range | System |

|---|---|---|

| Flow Rate | 8.0 – 10.0 L/min | Cooling Systems |

| Pressure | ~3.5 bar | Cooling Systems |

| Air Pressure | Varies | HVAC |

Fluid Mechanics: Theoretical Insights

Understanding fluid mechanics is critical when dealing with flow rate and pressure. These principles help engineers design efficient systems by modeling fluid dynamics accurately. Systems must adhere to these principles to avoid cavitation, reduce drag, and maintain structural integrity.

System Safety and Maintenance

Regular checks on flow rate and pressure can help identify leaks or blockages early. This proactive approach prevents potential system failures and ensures safety, particularly in high-pressure systems where breaches can lead to dangerous scenarios.

Optimization for Longevity

By optimizing flow rates and maintaining pressure levels, systems can operate more efficiently, reducing wear and tear on components. This optimization can lead to significant cost savings over time through reduced maintenance costs and prolonged equipment lifespan.

How Often Should You Inspect Pipes and Connections?

Regular inspection of pipes and connections is essential for maintaining a functional plumbing system and preventing costly damages. But how frequently should these inspections occur to ensure optimal performance and safety?

For residential properties, inspecting pipes and connections every 1-2 years is recommended. However, older homes or those with a history of plumbing issues may require more frequent checks. Commercial settings often need annual inspections.

Factors Influencing Inspection Frequency

Age of Property

Older homes, particularly those built before modern plumbing standards, are more susceptible to corrosion, leaks, and other issues. Inspecting pipes and connections in such properties every year is advisable.

| Property Age | Inspection Frequency |

|---|---|

| Newer Homes | Every 2-3 years |

| Older Homes | Annually |

Material of Pipes

Different pipe materials have varying durability. For instance, copper pipes are less prone to leaks than PVC. Understanding the material helps tailor inspection schedules.

- Copper Pipes: Every 3-5 years

- PVC Pipes: Every 2 years

- Galvanized Steel: Annually (due to corrosion risk)

History of Plumbing Issues

If your property has a history of leaks or other plumbing issues, more frequent inspections might be necessary. Consider scheduling bi-annual checks if issues are recurrent.

Benefits of Regular Inspections

Prevention of Major Damages

Routine inspections help identify small leaks or weaknesses in the plumbing system before they escalate into significant problems, saving on repair costs.

Ensuring Water Quality

Inspections can also reveal rust or corrosion that might contaminate drinking water. This is particularly vital in residential settings.

Compliance with Local Regulations

Some regions have specific requirements for plumbing maintenance, especially in commercial properties. Adhering to these ensures compliance and avoids penalties.

By considering these factors and tailoring your inspection schedule accordingly, you can maintain a robust plumbing system that minimizes unexpected repairs and ensures longevity. Understanding your property’s specific needs is crucial in determining how often to inspect pipes and connections for optimal performance and safety.

What Role Does Thermal Paste Play in Cooling Efficiency?

Thermal paste might seem insignificant, but it plays a crucial role in cooling your PC components. Without it, the efficiency of heat transfer from the CPU to the heatsink would drastically decrease, leading to overheating.

Thermal paste enhances cooling efficiency by filling microscopic gaps between the CPU and heatsink, ensuring optimal heat transfer. This prevents overheating, maintains performance, and prolongs component lifespan.

Understanding Thermal Paste’s Function

When you mount a heatsink onto a CPU, there are microscopic gaps between the two surfaces. These gaps trap air, which is a poor conductor of heat. Thermal paste fills these gaps, allowing for efficient heat transfer.

Types of Thermal Paste

There are different types of thermal pastes, including ceramic-based, silicone-based, and metal-based. Each has its own set of advantages:

| Type | Advantages |

|---|---|

| Ceramic-Based | Non-conductive and easy to apply |

| Silicone-Based | Good thermal conductivity and longer lifespan |

| Metal-Based | High thermal conductivity, ideal for overclocking setups |

Application Process

To maximize cooling efficiency, it’s crucial to apply thermal paste correctly:

- Clean Surfaces: Use isopropyl alcohol to clean the CPU and heatsink surfaces.

- Apply Paste: Squeeze a small amount in the center of the CPU.

- Mount Heatsink: Attach the heatsink evenly to spread the paste.

Improper application can lead to thermal issues that might cause overheating.

Maintenance and Reapplication

Over time, thermal paste can dry out, reducing its effectiveness. Regular checks and reapplication are recommended every couple of years to maintain optimal cooling. This is especially important if you disassemble your components frequently.

Common Mistakes

- Using Too Much: Applying excessive paste can reduce cooling efficiency.

- Uneven Spread: Leads to hot spots.

- Skipping Replacement: Old paste can hinder performance.

Understanding these aspects of thermal paste usage can significantly enhance your system’s performance. For more detailed guides on proper thermal paste application and maintenance practices, consult comprehensive online resources or manuals specific to your CPU model.

Conclusion

Maintain the Antminer S21 XP Hyd‘s coolant system by regularly checking levels, using quality coolants, monitoring flow rates and pressure, and inspecting components for optimal performance.

- Understanding the correct coolant type ensures compatibility with your vehicle, preventing potential damage or inefficiencies.

- Recognizing dashboard warning lights helps you address potential issues quickly, maintaining vehicle safety and performance.

- Adjusting coolant mixtures prepares your vehicle for temperature fluctuations, preventing freezing or overheating.

- Explore this link to learn about additives that protect against corrosion, crucial for maintaining metal components in mining rigs.

- Discover how inhibitors can prevent moisture damage in high humidity environments, ensuring your mining equipment remains operational.

- Check this source for manufacturer-recommended coolants tailored for various Antminer models to ensure optimal performance.

- Learn how specific maintenance practices enhance the efficiency and lifespan of mining hardware cooling systems.

- Explore the fundamental principles of fluid mechanics that influence system design and efficiency.

- Find strategies to enhance system efficiency by optimizing flow rates and maintaining proper pressure levels.

- Copper pipes offer longevity and resistance to bacteria growth, making them ideal for residential plumbing systems.

- Good water quality ensures safe drinking water and prevents potential health hazards from contaminated sources.

- Understanding regulations helps ensure compliance, avoiding fines, and maintaining safe operations.

- This link offers an in-depth explanation of how thermal paste enhances heat transfer and prevents overheating.

- Explore common mistakes made during thermal paste application that can lead to cooling inefficiencies.

- Discover recommended practices for maintaining optimal cooling through regular thermal paste reapplication.